Summary

This document explains how to install the Bronze Disk Pads to Machines

Instructions for Attaching Bronze Disk Pads to Machines

1. Using the VTAG or other documentation, determine where you will mount the pad. Consider any interference that may prevent mounting the sensor or routing the cable. When mounted, the sensor should not touch anything other than the pad and the cable should not be overly stressed or bent.

2. After tagging out the machine, remove any coupling guards or any other devices that prevent access to the site for the preparation of the surface and attaching the pad.

3. Using dry rags, clean the mounting area to ensure all oil, water, dirt, and other debris are removed. If any of these substances are dripping into the area, build a temporary dam to prevent this.

4. Using a portable grinder, a spot facer tool, or flat file to remove all paint from the area where the pad will attach to the bearing housing.

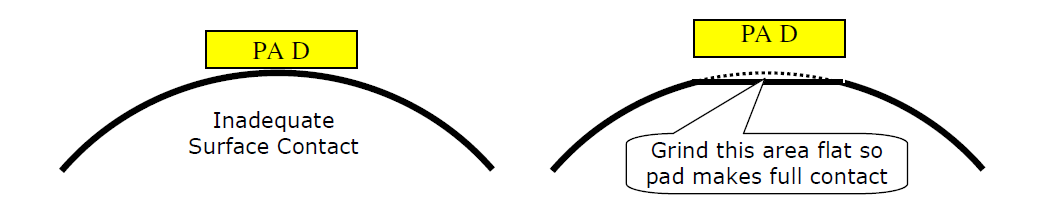

5. If the bearing housing is a curved surface, use the grinder or spot facer tool to create a 1” diameter flat surface.

6. Using a dry rag and a degreaser (acetone, lacquer thinner), clean the bearing housing area where the pad will be attached ensuring a dry, oil free, and clean surface.

6. Using a dry rag and a degreaser (acetone, lacquer thinner), clean the bearing housing area where the pad will be attached ensuring a dry, oil free, and clean surface.

7. Use a dry rag and degreaser to clean the surface of the pad that will mate with the bearing housing. Sometimes the pads have machine oil that is still attached from the manufacturing process used to build the pad.

8. Ensure the adhesive you are using is not beyond its code expiration date. Most adhesives are only good for about 1 year after opening. If in doubt, start with new adhesive.

9. Apply the activator / catalyst (Loctite 7380) to entirely coat both surfaces. Allow to dry for about 30 seconds.

10. Apply a liberal drop of adhesive (Loctite 325) to the surface of the pad and immediately press the pad onto the bearing housing in the proper orientation per VTAG. Hold the pad in place for an appropriate amount of time for the catalyst

to begin its reaction with the adhesive. This is typically about 30 seconds to one minute.

11. After 1 hour, wipe up any excess adhesive that dripped from the pad. For sensors used within an online system it is ok to attach the accelerometer and secure the cable after one hour.

12. The bond is fully cured in 24 hours and is adequate for collecting data within 3 hours.

13. For pads used within the portable data collection program, place a red plastic cap over the pad to keep paint / sediment from fouling the tapped hole.

14. Re-install the coupling guards taking care to ensure they do not touch the sensor or cause stress to the cable.

Comments