In researching Symphony Industrial AI products such as our TRIO data collectors, you should be familiar with hazardous location standards and whether our equipment is right for your environment. Such standards are for safety purposes and focus on the prevention of dangerous explosions due to the ignition of gases, dust, or fibers, especially by electronic components.

There are two common standards of hazardous location classifications: ATEX, used in the United Kingdom and Europe, and CSA, used in the United States and Canada.

ATEX uses two main categories of area classification: Group and Zone

Group I: presence of methane and dust

Group IIA: presence of propane

Group IIB: presence of ethylene

Group IIC: presence of acetylene or hydrogen

Group III: presence of combustible dust

Zone 0: continuous or frequent presence of gas*

Zone 1: occasional presence of gas

Zone 2: lacking or rare presence of gas

*Dust is similarly expressed as Zone 20, 21, and 22 respectively.

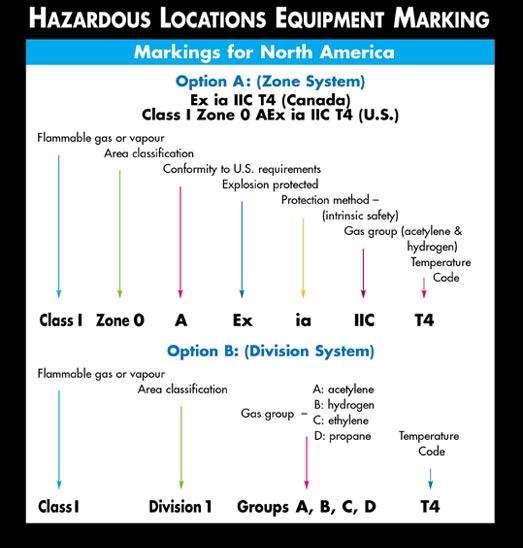

CSA uses three main categories of classification: Class, Division, and Group

Class I: presence of flammable gases or vapors

Class II: presence of combustible dust

Class III: presence of combustible fibers

Division 1: constant presence

Division 2: occasional presence

Group A: acetylene

Group B: hydrogen

Group C: propane and ethylene

Group D: benzene, butane, methane, and propane

Group E: metal dust

Group F: charcoal and carbon

Group G: flour, starch, wood, and plastic

Temperature Code

There are additional standards when it comes to the types of protection that equipment is capable of. Equipment markings commonly include both the zones that they are expected to operate in safely, but also additional equipment-only markings. To use ATEX as an example, markings include temperature rank, which must be less than the ignition temperature of the gas in the atmosphere, and EPL, one or more facets of equipment protection.

T1: 450°C

T2: 300°C

T3: 200°C

T4: 135°C

T5: 100°C

T6: 85°C

a: very high degree of safety (can be used in all three Zones)

b: high degree of safety (can be used in Zones 1 and 2)

c: conventional degree of safety (can only be used in Zone 2)

d: flameproof

e: increased safety

o: oil-filled

q: powder-filled

m: encapsulated

p: pressurized

i: intrinsically safe*

n: non-incendive

*Intrinsic Safety is a type of hazardous location protection, and is typically associated with electrical equipment. Although it is not as protective as the "non-incendive or non-sparking" rank, which is non-sparking, any sparks emitted have insufficient energy to ignite any surrounding gas or dust.

In general, ATEX rankings are far more complicated than CSA rankings. The only exception is in temperature rankings, in which CSA uses the same ATEX divisions, but adds additional divisions within the overall range of temperatures:

T2A: 280°C

T2B: 260°C

T2C: 230°C

T2D: 215°C

T3A: 180°C

T3B: 165°C

T3C: 160°C

T4A: 120°C

Reading the Label

For example, "Zone 0 nA IIC T4" is a four-piece marker for ATEX. The first part, "Zone 0", denotes the constant presence of a gas. The second part, "nA", is a special EPL code that stands for a very safe non-sparking device, similar to the "na" code, a combination of two protection facets. The third part, "IIC", refers to the IIC group of gases, which contains acetylene and/or hydrogen. The final part, "T4", means that no component on the equipment will exceed 135°C.

The traditional CSA equivalent would look like this: "Class I Division 1 Group A, B, C & D T4"

Comments