This paper describes, in brief, the issues involved in justifying a computer-based predictive maintenance program. A general formula for cost-benefit analysis is proposed, which can be tailored to your particular process. There are many issues involved in deciding whether to initiate a predictive maintenance program. Even if a program is already in place, it is often difficult to quantify the benefits of implementing a computer based system such as ALERT. The intention is to clarify the extent to which ALERT can have your process running more safely and efficiently, and is to be used as a rough guide only. Symphony Industrial AI makes no guarantees, implied or otherwise, with regard to the information herein.

Predictive Maintenance

The basic principle of predictive maintenance is to take such measurements that allow your organization to predict when plant machinery will break down. These measurements include machine vibration and plant operating data such as temperature, pressure and oil metal concentrations.

Preventative Maintenance

Preventative maintenance schedules regular machine/plant shutdowns, irrespective of whether repairs are required. There are many problems associated with this maintenance strategy including:

•Increased maintenance costs as parts are replaced when they are not necessarily required.

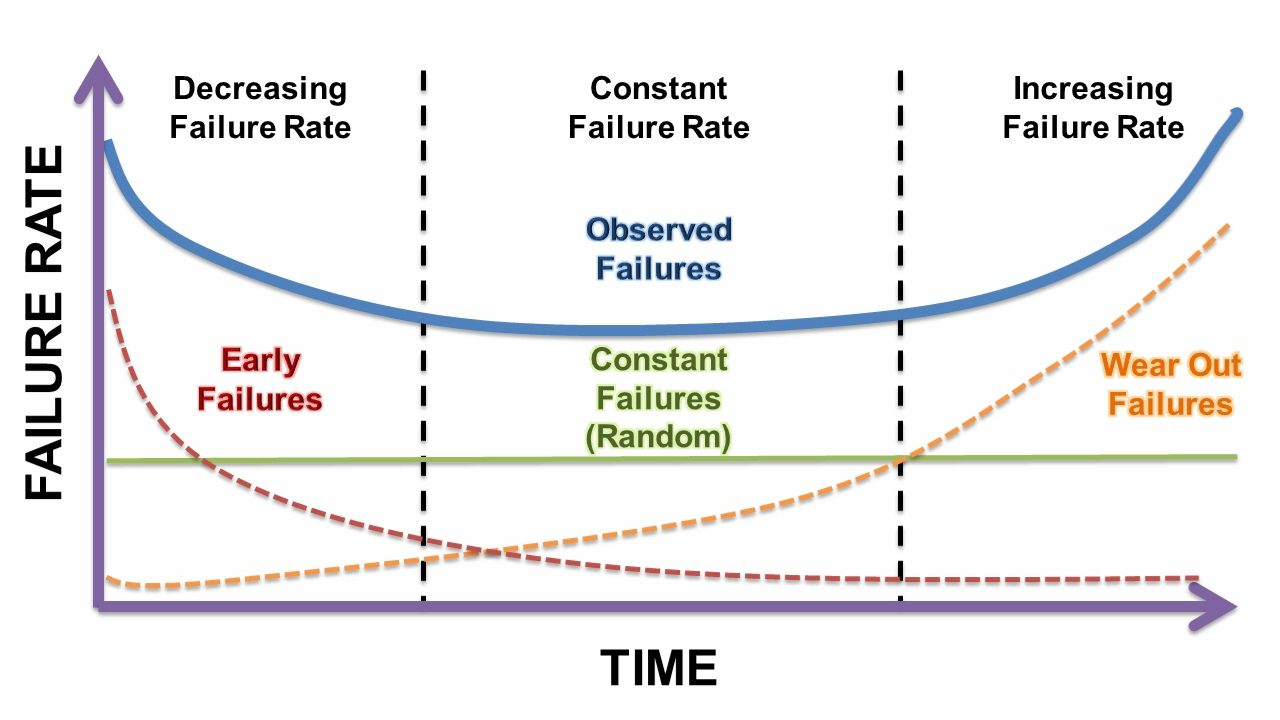

•Risk of infant mortality due, for example, to human error during dismantling work. The component life cycle chart shown here identifies that, by far, the greatest probability of assembly failure is at start-up.

Benefits of Predictive Maintenance

Predictive maintenance, on the other hand, determines when the machine REQUIRES repair. Plant machinery is therefore only repaired WHEN REQUIRED. The benefits of predictive maintenance can be separated into two main categories.

INCREASED SAFETY: Predictive maintenance provides the reassurance of safe, continued plant operation. By reducing the likelihood of unexpected equipment breakdown, the safety of employees is improved. Although difficult to quantify, there is a definite economic benefit in improved employee and union relationships.

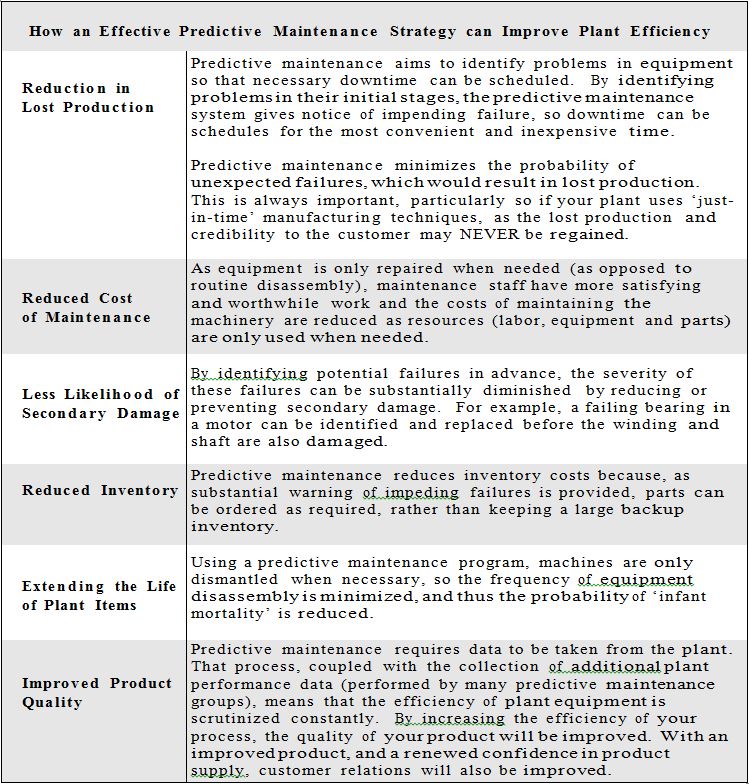

IMPROVED OPERATING EFFICIENCY: There are many areas in which a predictive maintenance program can increase the efficiency of your process. Please see chart below.

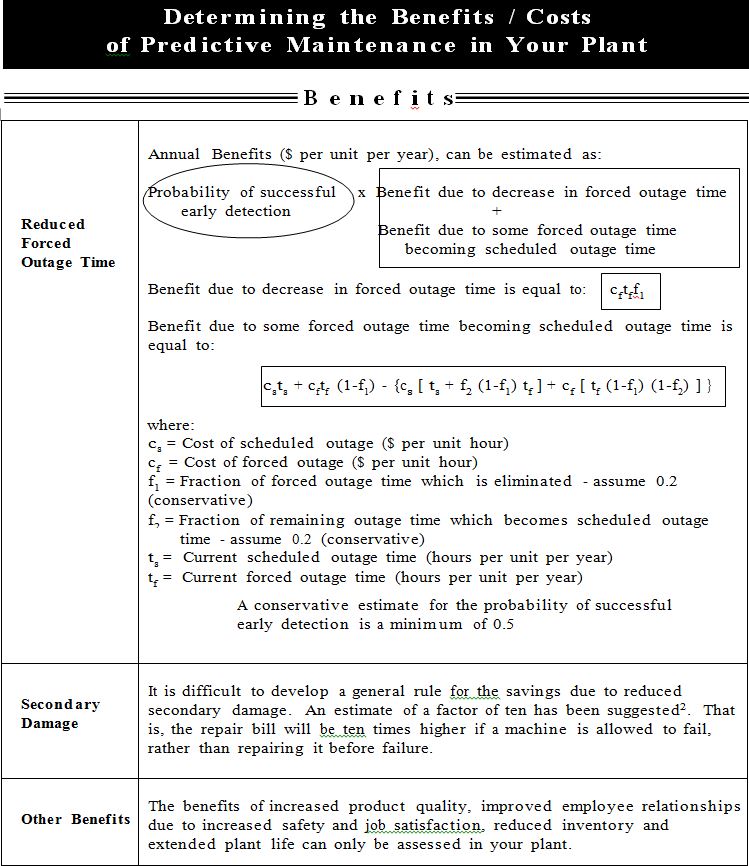

Thus, the benefits of using ALERT to manage your predictive maintenance program can be readily estimated. ALERT allows you to optimize on these savings.

Comments