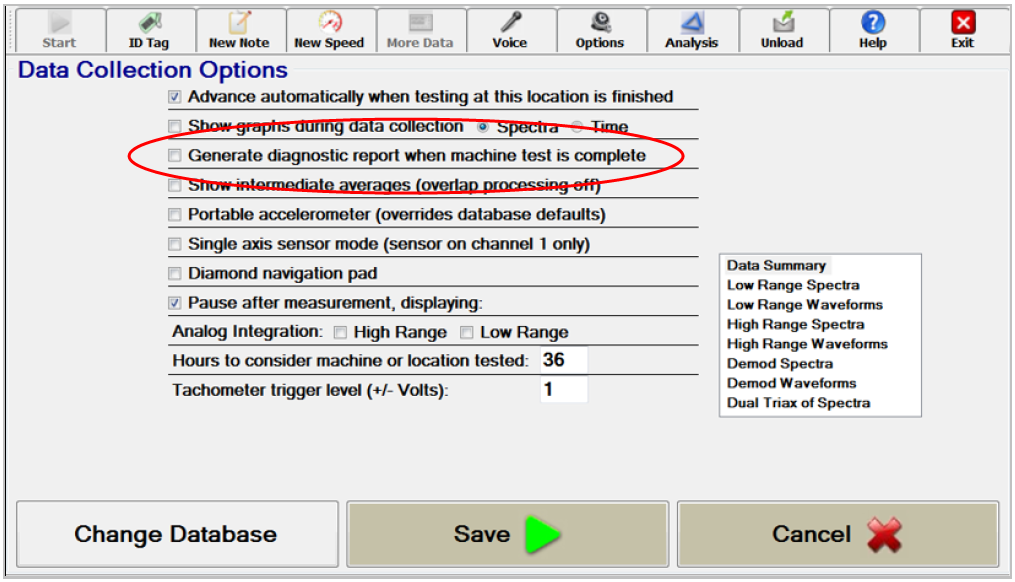

The TRIO data collection software, Collector (CA-series) or Collector-X (CX-series), has an option setting that will allow the user in the field to see automated diagnostic results upon completion of data collection.

There are various reasons for having this enabled or disabled.

Many users, especially TRIO CX-series users, prefer to have immediate automated diagnostics upon completion of collecting all test locations on a machine of interest. The data are compared to either a synthesized average baseline or real average baseline if one is established. CX users can review and confirm the automated diagnostic finding in the ExpertALERT software on the TRIO in field if desired.

The CA-series data collectors also have this same settings option. However, on a CA-series TRIO, the automated diagnostic that is created is merely a screening or exception result which will identify severity of machine based on the average comparison.

There are several factors to consider if deciding to check this option:

- New programs. Customer who have just started a new program or programs which otherwise have little or no real average baseline is receiving automated diagnostics with limited diagnostic criteria. Though the synthesized average baseline is a great starting point for analysis, presenting this information to the user in-field could be misleading and premature. It is advised that with new programs, the user would collect a significant number to machine test to develop the average baseline for each MID. Once the program has been groomed and the automated diagnostics reach a more accurate state (6-8 tests representing a healthy machine), then the user should turn this option on.

- Programs with remote analysis. The TRIO data collectors are designed to have data collection performed by technicians and operators while the analyst diagnose machinery remotely or separated from the machine. Not requiring an engineer or analyst to be in the plant could put the diagnostics out of context. While the automated diagnostic could be presenting a fault a machine could potentially have, the analyst is weighing that fault against the historical trend, other PdM technologies, repair history, and many other factors. It is easy to mis-interpret the severity of fault without having this analytical perspective. It is recommended to leave this option unchecked for the simplification of the collection process.

- Speed of collection. Though certainly the processors of tablet computers provides the automated diagnostics in mere seconds following data collection, there is generally time spent by technicians in the field looking through these results to make an understanding of the fault. To help speed up the data collection process it could be advantageous to keep this option unchecked. This will help technicians and operators stay focused on merely just collecting the data and moving on.

It should be noted that this setting applies to all machines that are being tested with the controller.

Comments