Release date: June 24, 2022

Deliverable Summary:

Determines and displays asset setup status for achieving certification criteria required for fully automated analysis. The automated diagnostic system will evaluate the parameters that define the Machine Internal Design (MID) to determine the completeness of the MID and asset to provide accurate automated diagnostic results.

Definition:

To have accurate automated diagnostics (including reducing false positive and false negative results), it is important to have complete information about a machine and its MID. In addition to providing a score that represents the completion, users needs to understand what information may be missing in order to complete the setup. An asset completion profile would present a percentage of completion and identify the gaps.

Usage:

The objective of the completion profile is to identify gaps that are required to be resolved in order to certify and eventually lock the MID by an analyst.

Analysts should be able to understand the parameters missing during the time of analysis so as to potentially complete the profile immediately upon each data submittal. Example, add number of motor bars that is understood as missing but identifiable in the vibration data.

Release Information and Examples:

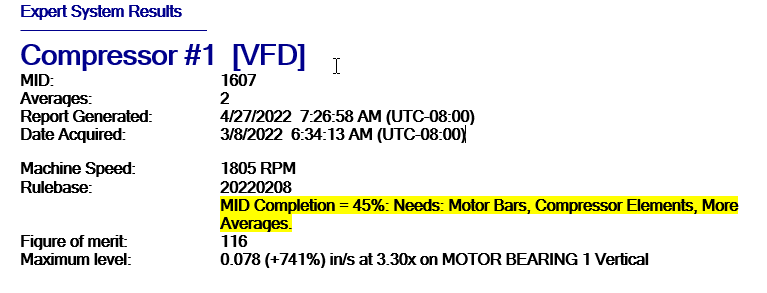

The report section in EA will now contain messages that provide the Analyst with a percentage that indicates the relative completeness of the tested MID. The completion also provides messages to direct the analyst to areas that are missing information. The completion information appears only in the Expert System Result and does not appear in the Reviewed Analyst Result nor the PredictivePortal.

See highlighted section below:

The MID completion algorithm executes several steps to determine the required and desired fault codes for the given MID configuration.

It checks the asset for the presence of a speed changer (belt/chain or gear), type of driver, type of driven component etc., to determine which fault codes are required and/or optimum.

The algorithm checks whether there is a driver fault code and a driven fault code. If direct drive or a driven fault code is not required, it only searches for a driver fault code. In addition to the standard 1X driven fault codes, it also accepts the codes: S1, S2, CS1, CS2 etc. typical of multi shaft machines.

Additional component specific fault codes are then checked. If the MID contains a belt, it looks for BR or 2BR. The same is true for the remaining components.

The following component fault codes are checked:

- Belt: BR, 2BR

- Gear: HG, LG, GR, G1

- Motor: MB

- Pump: PV, PP, PB, PT

- Fan: FB

- Compressor: CV, , CT, BL, CV1,CV2

- Turbine: TB1, TB2

- Generator: GB, GS

- Diesel: EM, EP, EF, AG

Finally, the method observes the number of averages used. The completion profile assumes 6 or more averages is adequate for a complete profile. Any less and there is a corresponding decrease in the MID completeness percentage.

Comments